GRG fiberglass reinforced gypsum ceiling

Raw Materails: gypsum powder + additives + glass fiber wire

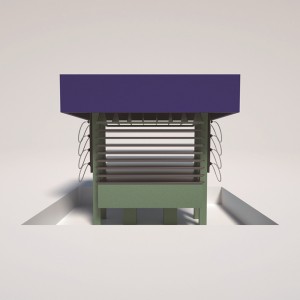

Equipment used: batching machine

Function: It is to match all the raw materials in a proportional manner during the

production process

Pulping

Equipment used: pulper, storage tank, mixer

Function: processing and mixing the well-matched ingredients with artificial

methods and mechanical methods

System board

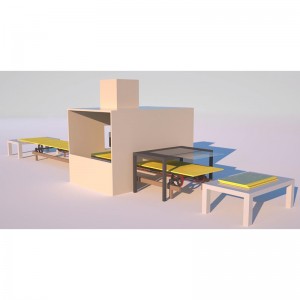

Equipment used: plate making machine

Function: It is to compress the product using tools

De-moulding

Equipment used: de-moulding machine

Function: Separate the plate-making products from the mold. There are three methods for stacking a series of products. 1. Manual palletizing. Lighter objects.

Palletizing by forklift. More commonly used in the warehouse.

Crane palletizing. Production lines and heavy objects are commonly used.

|

General overview of high crystal gypsum ceiling production equipment |

|||

| No. | Name | Details | remarks |

| 1 |

Total power of equipment |

40KW | |

| 2 | Equipment size | 70×1.6×2.1(m) | Length x width x high |

| 3 | Mold size | 680×680×20(mm) |

Mold color and inner diameter are customized according to customer requirements |

| 4 | Number of molds | 200 pcs | |

| 5 | Equipment output | 500-700 PCS | Output per hour |

| 6 | Labor | 4-5 persons | |

| 7 | Site requirements | 80×4(m) | Length x width |

| 8 |

Storage silo capacity |

60m³×2 | |

| 9 | Storage bin site | 200 ㎡ | |

| 10 | Drying rack size | 6×1×(2.1-1.9)(m) | Length x width x high |

| 11 |

The drying board is structured (optional items) |

Angle iron, asbestos tile, reinforced column, rubber pad, reinforced column rubber sleeve |

4# thickness wall angle iron-11 pieces, asbestos tile-9 pieces; rubber pad-48m, Reinforced column -504, reinforced column rubber sleeve -504 |

| 12 | Number of drying racks required (optional items) | 200 PCS |

Quantities of drying racks required for one equipment and one drying Period |

| 13 | The required place of board Drying(optional items) | 4500 ㎡ |

The required place of board Drying(optional items) |

| 14 |

The required place of board Drying(optional items) |

15-20 days | |