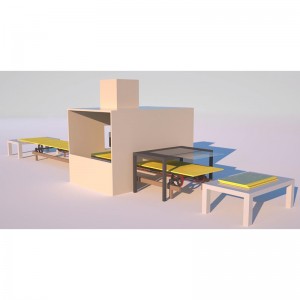

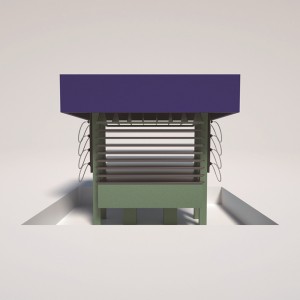

High speed dispersion mixer

1. When stirring and dispersing, the air absorption is very little, and the mixing and mixing effects are good. With medium or high speed stirring, the dispersion can make the substance dissolve rapidly and the particles become smaller. The very fine solid particles are added into the liquid to make the suspended particles. The characteristics of the suspended particles are that they are not subject to the gravity and precipitate.

2. The surface of a solid particle is wetted with a liquid base material.

3. The particles are broken up into smaller particles by mechanical energy.

4. The characteristic interaction between particles and liquid base materials determines the power of wetting and flocculation.

5. The interaction between solid particles and liquid base material determines the wetting and anti flocculation effects.

6. Applicable materials: coating, fuel, pigment, latex paint, ink, paper, adhesive and other chemical industries for liquid and liquid solid materials.

|

Size |

1.9x0.5x0.9M |

|

Powder |

12KW/H |

|

Machine No. |

HMG |

|

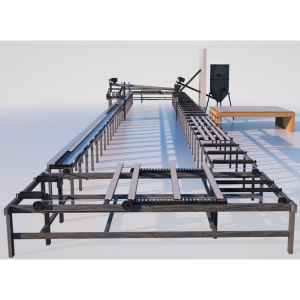

Site requirement |

Reserved water interface ,electrical interface.Drainage channel and sewage channel.Voltage 380V/220V |

|

Operator |

1-2 workers |

|

Equipment output |

500KG/per hour |

|

Weight |

950KG |

1. Efficient and Innovative sample service, IATF 16946:2016 quality control system.

2. Professional online service team, any mail or message will reply within 24 hours.

3. Advanced production equipment, strict quality testing and control system to make sure superior quality.

4. Competitive price: we are a professional auto parts manufacturer in China, there is no middleman's profit, and you can get the most competitive price from us.

5. Good quality: good quality can be guaranteed, it will help you keep the market share well.

6. Fast delivery time: we have our own factory and professional manufacturer, which save your time to discuss with trading companies. We will try our best to meet your request.